Bolts Cracking During Torque Testing: What Solar EPC Teams Must Understand

Few things create panic onsite like a bolt breaking during torque testing.

Your staff is ready.

Structure positioned.

Wrench clicks…

And the fastener fails.

Not a minor chip —

a full split.

This isn’t a coincidence. It’s a quality warning.

Why Bolts Crack Instead of Tightening

Solar bolts fail during torque mainly due to:

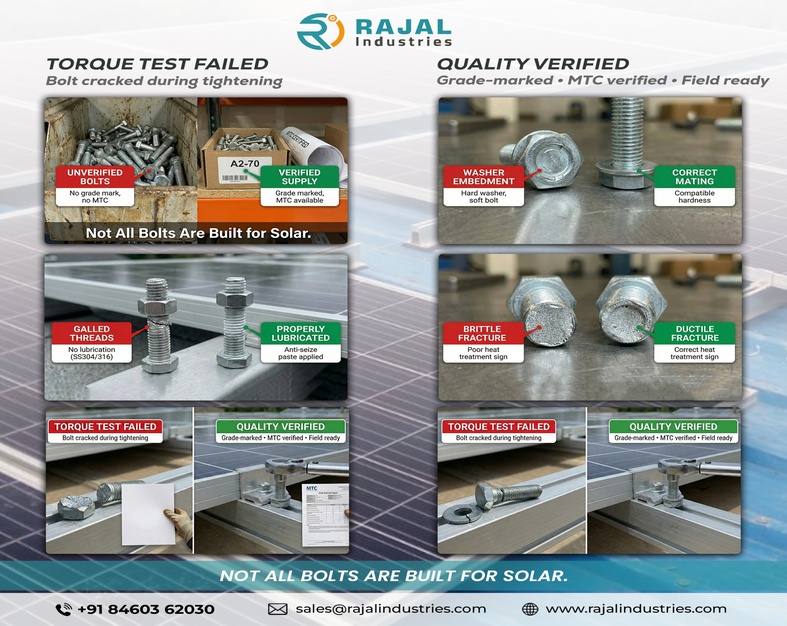

1. Wrong Grade Supplied

- Sometimes bolts are sold as 8.8 but are actually 4.6 or 5.6.

Visually identical.

Structurally weaker.

High torque reveals the truth the stamp didn’t. - 2. Poor Heat Treatment

Improper quenching or tempering leads to:

• Brittle structure

• Micro-cracks inside

• Low fatigue resistance

Externally the bolt looks strong.

Internally it’s ready to fail.

3. Low-Quality Raw Material

- Inconsistent alloy composition leads to:

• Weak tensile strength

• Reduced toughness

• Crack formation under load

If the steel itself is bad — no process can fix it later

4. Hard Washer + Soft Bolt

- Using high-hardness washers with low-grade bolts?

The washer survives.

The bolt absorbs the stress.

And then… fractures.

Typical Sizes Where Torque Failures Are Seen

Based on field experience:

• M10 HDG bolts

• M12 anchor bolts

• SS304 M8/M10 bolts without lubrication

• Mixed-batch fasteners used together

• Stainless bolts used without wax coating

What You Should Always Verify Before Installing

✅ Grade stamped on head (8.8 / A2-70)

✅ MTC with heat number

✅ Supplier QC report

✅ Zinc coating thickness for HDG

✅ Washer compatibility

✅ Storage condition before use

If any of those are missing —

you’re installing blind.

Final Word

When a bolt breaks during torque:

It isn’t just a bad part.

It’s a break in trust.

Solar structures don’t get a second chance after commissioning.

One weak fastener can become a failure point.

If you want reliability in the field —

you need strength at the unit level.