"Rajal Industries: Innovating Precision Stamped Parts for Industrial Excellence"

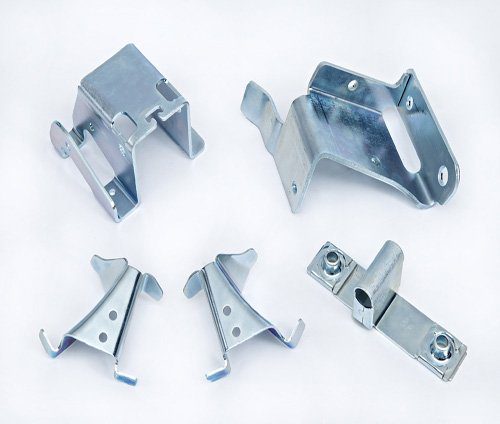

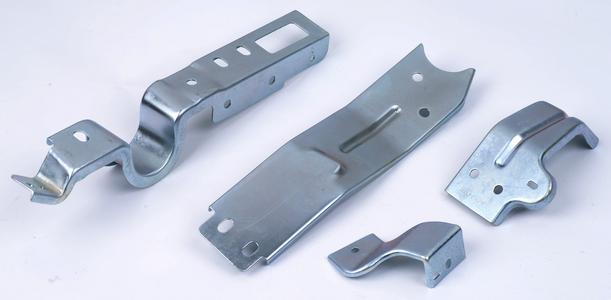

Rajal Industries excels in manufacturing high-precision stamped parts and stamped bent parts, offering unparalleled quality in various metals for diverse industrial applications. Our commitment to utilizing cutting-edge stamping and bending technology, combined with our technical expertise, positions us as a leading provider for industries seeking continuous quality, rapid turnaround, and cost-effective solutions. We cater to both large-scale productions and custom small series, ensuring versatility and precision in every product.

Enhanced Technical Overview of Our Stamped Parts

1. Product Type:

1) Diverse Material Range:

Specializing in fabricating sheet metal stamped parts from an array of materials including stainless steel, steel, aluminum, brass, and other non-ferrous metals.

2) Advanced Manufacturing Techniques:

Employing state-of-the-art stamping processes to create parts with intricate shapes and fine tolerances, suitable for various industrial applications.

2. Materials and Specifications:

1) High-Grade Selection:

Utilizing materials like steel (Standard: AISI 1020), high-grade steel (Standard: AISI 304), brass (Standard: C26000), and copper (Standard: C11000), alongside light metal and spring steel for specialized applications.

2) Custom Material Solutions:

Offering material selection based on specific industrial needs, ensuring optimal performance and longevity.

3. Strength Classes and Material Strengths:

1) Engineered for Durability:

Providing strength classes from 3.6 to 12.9, accommodating heavy-duty to light applications.

2) Thickness Precision:

Material strengths ranging from 0.5 to 4.5 mm, allowing for precise engineering based on the application's load-bearing requirements.

4. Additional Processing and Surfaces:

1).Customized Processing:

Offering additional processing such as shank slots, and various dog point designs for specialized applications.

2).Surface Treatments:

Delivering a range of finishes like galvanized (Standard: ASTM B633), nickel- plated, achromatised, and others to enhance corrosion resistance and aesthetic appeal.

5. Coatings and Heat Treatment:

1).Advanced Coating Techniques:

Applying coatings as per VDA, PPAP standards on request, providing extra protection and improved physical properties.

2) Heat Treatment Options:

Including annealing, carbonitriding, and case hardening (Standards: ASTM A36 for annealing, SAE 8620 for carbonitriding), enhancing the mechanical properties of the stamped parts.

6. Batch Sizes and Documentations:

1) Flexible Production Capacity:

Adapting to both large-scale and small-scale production needs, starting from 30,000 pcs., with options for smaller quantities as per client agreements.

2)Comprehensive Documentation:

Providing detailed documentation for first sampling, including ISIR, VDA Volume 2, and PPAP levels, ensuring adherence to quality and industry standards.

Conclusion

At Rajal Industries, our deep-rooted expertise in stamped part manufacturing, combined with our commitment to quality and innovation, makes us a trusted partner for industries worldwide. Our extensive capabilities in producing precision-engineered stamped parts, from design to finish, assure our clients of products that meet their specific requirements with exceptional quality. Contact Rajal Industries for your stamped part needs and experience a partnership that brings technical excellence to your industrial projects.

| 1) Materials: | Steel, high-grade steel, brass, copper, light metal, spring steel |

| 2) Strength classes: | 3.6 – 12.9 |

| 3) Material strengths: | 0.5 to 4.5 mm |

| 4) Additional processing | Shank slots, oval half dog point, coned half dog point, long dog point |

| 5) Surfaces: | Galvanised (CrVI-free, RoHS-conform), nickel-plated, achromatised, Delta-Tone and Seal, Decrement, Geonet etc. according to automotive and electrical industry specifications (VDA standard) |

| 6) Coatings: | samples according to VDA, PPAP on request |

| 7) Heat treatment: | Annealing, carbonitriding, drawing, tempering, case hardening. Others on request |

| 8) Batch sizes: | from 30,000 pcs. (Smaller quantities by agreement) |

| 9) Documentations:: | Available for first sampling: Standard ISIR as cover sheet sampling; VDA Volume 2 Level 0-3; PPAP Level 1-3. |