Solar Panels Are Ready… But the Clamps Don’t Fit

Few things frustrate EPC teams more than this moment.

The panels arrive on time.

The rails are fixed perfectly.

The crew is fully ready.

And then… the clamps don’t fit.

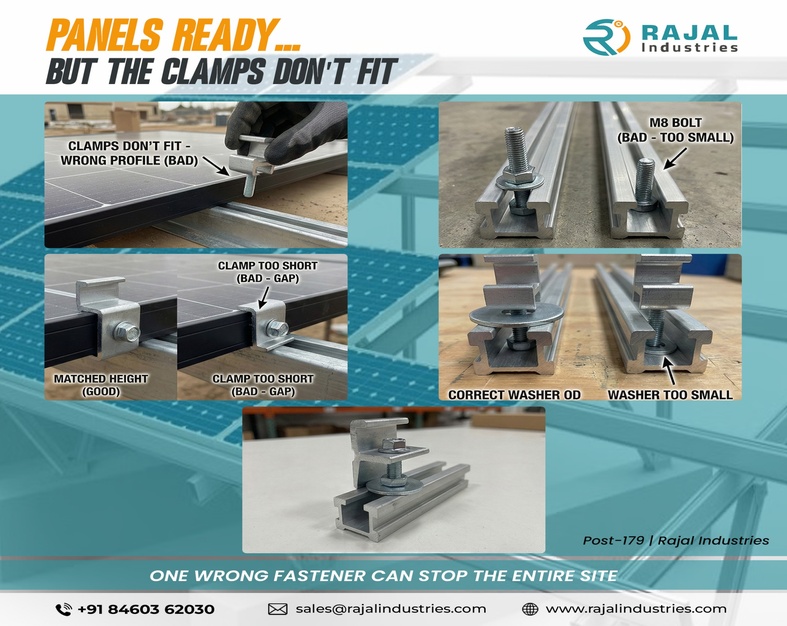

Wrong profile.

Wrong bolt.

Wrong washer size.

Suddenly the entire project stops.

Not because of engineering problems.

Not because of manpower.

Just because the hardware doesn’t match.

Why clamp mismatch happens so often

Most clamp problems start long before delivery.

They begin at procurement stage.

Some common reasons:

• Clamp selected before rail design was finalized

• Washer OD does not match rail slot width

• Wrong bolt diameter (M8 ordered instead of M10)

• Frame thickness not considered

• Procurement chooses “closest available”

• Size confirmed verbally, not by drawing

• Supplier sends mixed stock from warehouse

Hardware that looks similar on paper can behave very differently on site.

Real damage caused by wrong clamps

This is what EPC teams experience:

- • Site stoppage

• Labour cost loss

• Tool idle time

• Centre-of-passage delays

• Temporary local purchases

• Client dissatisfaction

• Permanent joint compromise

Improvising is not engineering.

Temporary solutions become permanent problems.

Common clamp and fastener mismatches

These combinations cause failures:

Clamp Height vs Module Frame

If the clamp is shorter, the panel loosens.

If it’s taller, torque is never reached.

1. Bolt Size Mismatch

M8 bolts on M10 slots = movement and failure.

M10 bolts in M8 slots = impossible fitting.

2. Washer OD vs Slot Width

OD too small = washer slips inside rail.

OD too large = clamp never seats properly.

3. Flange vs non-flange confusion

Procurement orders flanged bolts only.

Fixing becomes weak

How professionals prevent this mess

Good EPC teams follow these rules:

✅ Approve clamp samples before bulk

✅ Lock bolt size from structure drawings

✅ Match washer OD with slot dimension

✅ Standardize hardware within project

✅ Build one approved fastener kit per design

✅ Order clamps after final rail selection

✅ Never accept mixed packing

✅ Inspect material on arrival

Final words

When clamps don’t fit,

it’s not a warehouse problem,

it’s a design control problem.

The strongest structure fails

if one joint is wrong.

And clamps are the joints.

Fix the hardware once.

Avoid the delay forever.