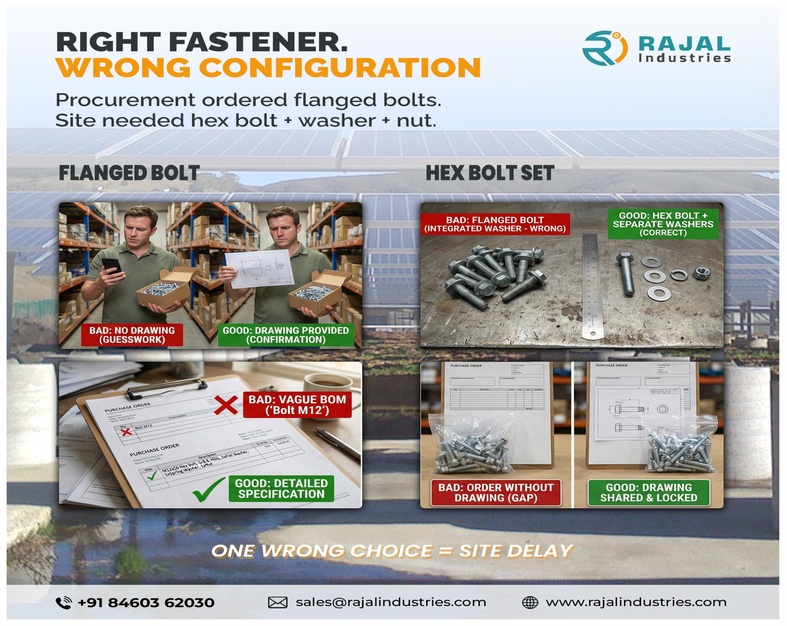

Solar Fastener Configuration Mistake: Flanged vs Hex Bolt

Procurement Ordered Correctly:

Site Failed Install.

Because the configuration was wrong.

If you work in solar EPC, you’ve seen this problem already.

The delivery arrives.

Boxes are opened.

Workers look confused.

Someone says:

“These are flanged bolts… We needed hex bolts with washers.”

And suddenly:

• Installation stops

• Supervisor calls procurement

• Procurement calls supplier

• Supplier checks drawings

• Everyone wastes time

Not because product quality was bad.

Because configuration was misunderstood.

Where It Goes Wrong

1) Flanged Bolt vs Hex Bolt Confusion

Flanged bolts come with built-in washers.

Hex bolts require:

• Plain washer

• Spring washer

• Nut

When these formats aren’t defined clearly, the supplier ships what is written, not what the site expects.

2) BOM Written in Short Form

“Bolt M10 HDG” is not specification.

It must say:

- • M10 × 30 mm

• Grade 8.8

• HDG coating

• Hex head

• With two washers + nut

OR

• Flanged serrated bolt with nut

Short BOMs create long delays.

3) Drawings Not Shared With Procurement

Engineering and procurement work separately in many EPC teams.

That gap creates:

- • Wrong bolt types

• Wrong washer OD

• Wrong thickness

• Wrong packing unit

Drawings must support every fastener order.

How Good EPC Teams Avoid This

✔ Confirm fastener type (hex or flanged)

✔ Define washer configuration

✔ Lock the drawing before ordering

✔ Ask for pre-dispatch photos

✔ Validate the packing set

✔ Demand specification matching

Fasteners don’t delay projects.

Configuration mistakes do.

Final Thought

Fasteners aren’t expensive.

But when one configuration is wrong,

the entire site pays.

If you control ordering,

control the details.