When a client looks at a bolt and asks,

“Where is the IS 1367 marking?

it’s not a casual question.

It’s about trust, quality, and accountability.

In solar EPC projects, fasteners may look small — but they carry the entire structure.

If a bolt does not show its grade or standard clearly, you don’t just lose confidence.

You risk inspection failure, client dissatisfaction, and future liability.

What is IS 1367 and why is it critical?

IS 1367 is the Indian Standard that defines mechanical properties, material grades, and dimensional tolerances for bolts, nuts, and washers.

It ensures:

A. Correct tensile strength

B. Verified material grade (such as 8.8, 10.9)

C. Uniform thread accuracy

D. Mechanical performance under load

E. Safety under vibration and environmental stress

If a fastener claims compliance, it must also show traceability through:

A. Head markings

B. Test reports

C. Batch identification

Common Issues Seen on Solar Sites

Here’s what repeatedly shows up at EPC sites:

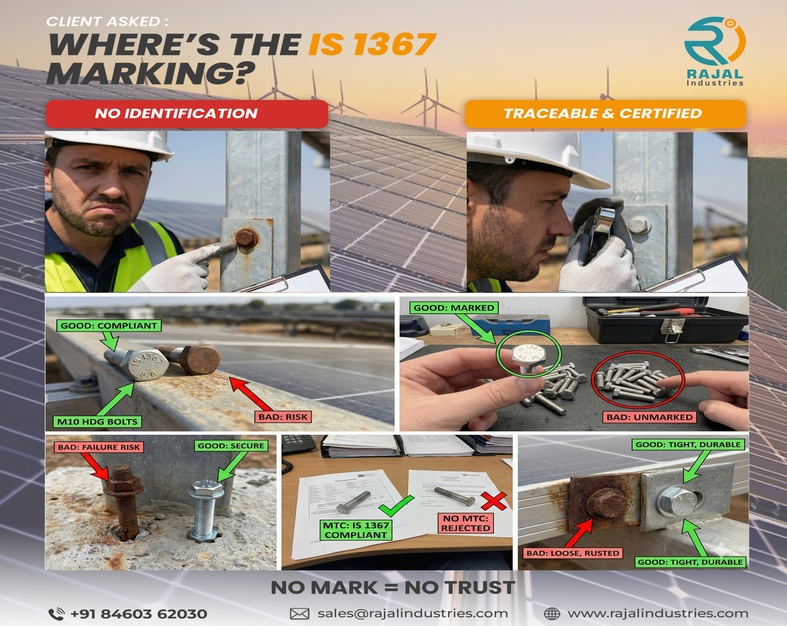

1. Bolt heads without grade marking

2. No MTC provided with dispatch

3. Mixed packing from different batches

4. Supplier verbally claims compliance but provides no proof

5. Installer installs before inspection due to schedule pressure

6. Audit comes later and flags everything

At that point, replacement becomes expensive and embarrassing.

Typical Solar Fastener Sizes Affected

Most audit problems show up around:

1. M10 × 25 / 30 mm HDG 8.8 bolts

2. M12 HDG anchor fasteners

3. Serrated flange nuts without stamping

4. Washers without thickness or grade confirmation

These are used across:

1. Module mounting

2. Rail connections

3. Earthing

4. Inverter skid frames

5. Structure foundations

Yet many go unchecked until it’s too late.

The Right Way to Verify Compliance

Before a single box opens on site, EPC teams should confirm:

✅ IS 1367 mentioned in purchase order

✅ Manufacturer’s identity on bolt head

✅ Test certificate with batch number

✅ Grade marking visible

✅ Thickness measurement for HDG

✅ Packing label with specification

If any one is missing, stop and confirm.

Why “looks okay” is dangerous

Fasteners fail slowly and quietly.

1. Rust develops

2. Torque drops

3. Joint loosens

4. Vibration increases

5. Load shifts

By the time the problem shows, the root cause is forgotten.

And the blame lands on the EPC.

Final Thought

Standards are not paperwork.

They are protection.

When a client trusts your fastening system,

they trust your entire project.